An exclusive canvas cleaning service : washing and restoration

UTILIS – Textile washing

Soft wall infrastructure is the key component to maintaining a rapid, go-anywhere capability. As with all tools, there is a need for maintenance which increases with frequency and duration of shelter use. The technical textiles used on modern shelters demonstrate prolonged operating life and maintained performance when subject to periodic deep cleaning. This also assures a safe, efficient and pleasant environment for system users.

In order broaden our support services available to clients we have implemented a dedicated washing, drying and packaging plant for shelter textiles at our Ennery HQ site. This comprises a high capacity washing system configured specifically for large textiles, two dedicated drying hangars with forced air heating totalling 600m2 and inspection and repackaging areas.

The new textile facility is ideally located at the heart of the transport network, termed ‘the crossroads of Europe’ for optimum logistical ease.

It is the only such machine in France and one of only 3 in Western Europe that allows the clean up to 700 m² of textile per wash.

The facility has the following features :

- 3 Full wash cycles per day

- Gentle 30oC wash cycle preventing textile damage

- Thorough detergent penetration for maximum cleaning quality

- Dual rinse cycle for assured detergent removal

- Accepts shelter/ marquee textiles of all weights, in both flat or shaped sections

UTILIS know very well that the continual cycling through setup/ operation/ teardown/ storage phases can be tough on equipment, especially when subject to the additional pressure of operational deadlines. In a perfect world, deployable infrastructure would always be taken down in dry conditions and packed according to system documentation, but we know that reality doesn’t always follow theory.

The UTILIS facility therefore offers high volume processing throughput to alleviate the maintenance burden for operators managing large shelter fleets/ textile stocks. Cleaning may be contracted in bulk for logistical economy/ simplicity or on a rotational basis in order to maximise the operational availability of systems.

After dispatch to site, the whole process is managed by UTILIS as a turnkey operation, resulting in the return of clean, dry, checked textiles to our clients.

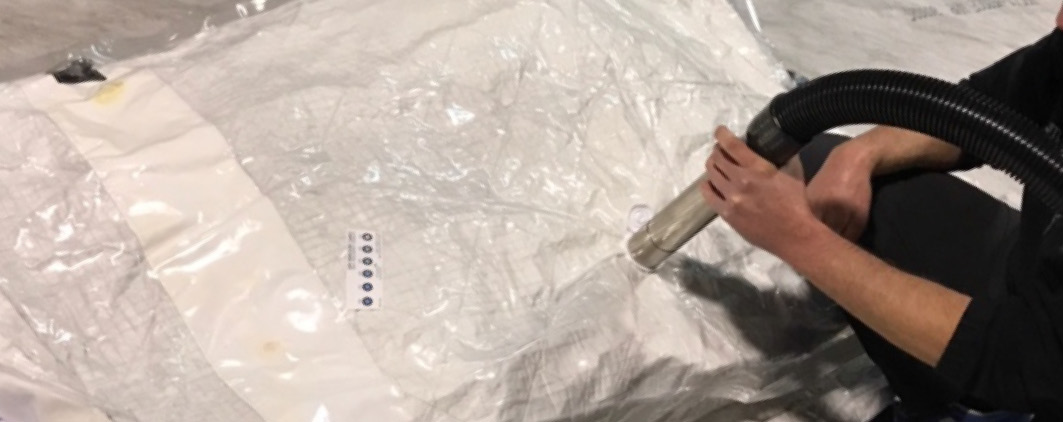

As an option, UTILIS can also apply an environmentally controlled protective packaging to textiles post-treatment for onward operational readiness storage. This allows for prolonged storage and multi-modal transport across all common climatic environments without any consequential impairment to the shelter systems.

Upon receipt of the textiles to be treated, UTILIS implements well-defined control procedures, performed by our experienced staff and trained to handle all stages of processing, including :

Reception check – Washing prepartion – Textile washing – Post wasing control – Assisted drying – Post-processing inspection – Controlled packaging (optional) – Preparation for transport

For the controlled packaging option, dried canvases are storage-prepared in a state of guaranteed operational readiness. Using comprehensive checking criterion, the state of all textile pieces are verified and documented. All textile elements are then subjected to a strict packaging protocol within a tightly controlled dryair environment to prevent entry of humid air within the packaging envelope. Textiles are then vacuum packaged with humidity indicators permitting simple visual checking to verify that protection remains intact.

This system provides an elevated level of protection and system preservation until the seal is broken at system deployment. This maximises system storage durations and textile longevity whilst minimising system maintenance burden and whole life costs.